Power Distribution Unit (PDU) manufacturers play a pivotal role in ensuring operational efficiency. I’ve seen how their innovative designs optimize power distribution, reduce energy waste, and enhance reliability. Companies like NBYOSUN lead this space with cutting-edge solutions. Their YS31542-36C13-6C19-M smart PDU exemplifies how advanced features can transform network performance and sustainability.

Smart PDUs deliver measurable benefits. For instance:

- Intelligent rack PDUs reduce energy waste by up to 20%.

- Continuous energy monitoring cuts energy consumption by 10-20%.

- High-efficiency transformers improve energy efficiency by 2-3%, driving cost savings.

These innovations directly impact cost savings, scalability, and environmental goals, making PDU manufacturers indispensable in today’s digital landscape.

Key Takeaways

- PDU makers are important for better power use and work efficiency.

- Smart PDUs can cut energy waste by up to 20%, saving money.

- PDUs with live monitoring find problems fast, so fixes happen quickly.

- Remote control lets workers manage power from anywhere, reducing delays.

- PDUs with flexible designs help businesses grow while staying dependable.

- Using energy-saving PDUs helps the planet by lowering energy use and pollution.

- Picking a trusted PDU maker with many options fits different business needs.

- Good customer support from makers keeps systems running well and saves time.

The Role of PDU Manufacturers in Power Distribution

What Are PDUs and Why Are They Important?

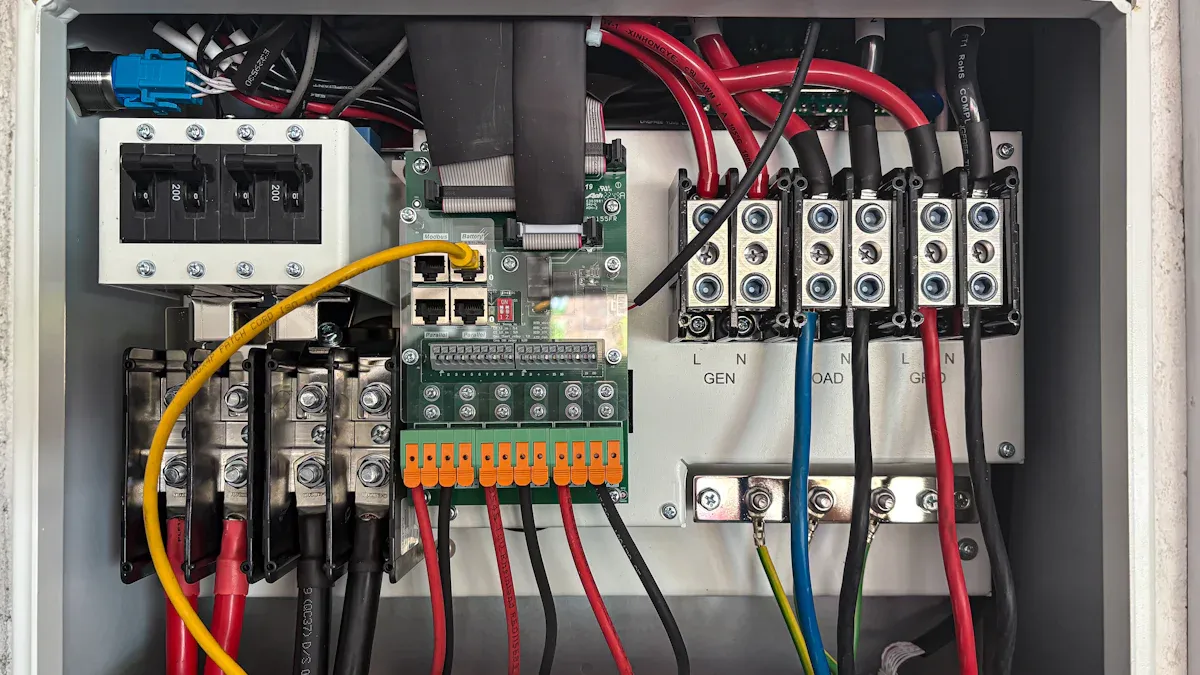

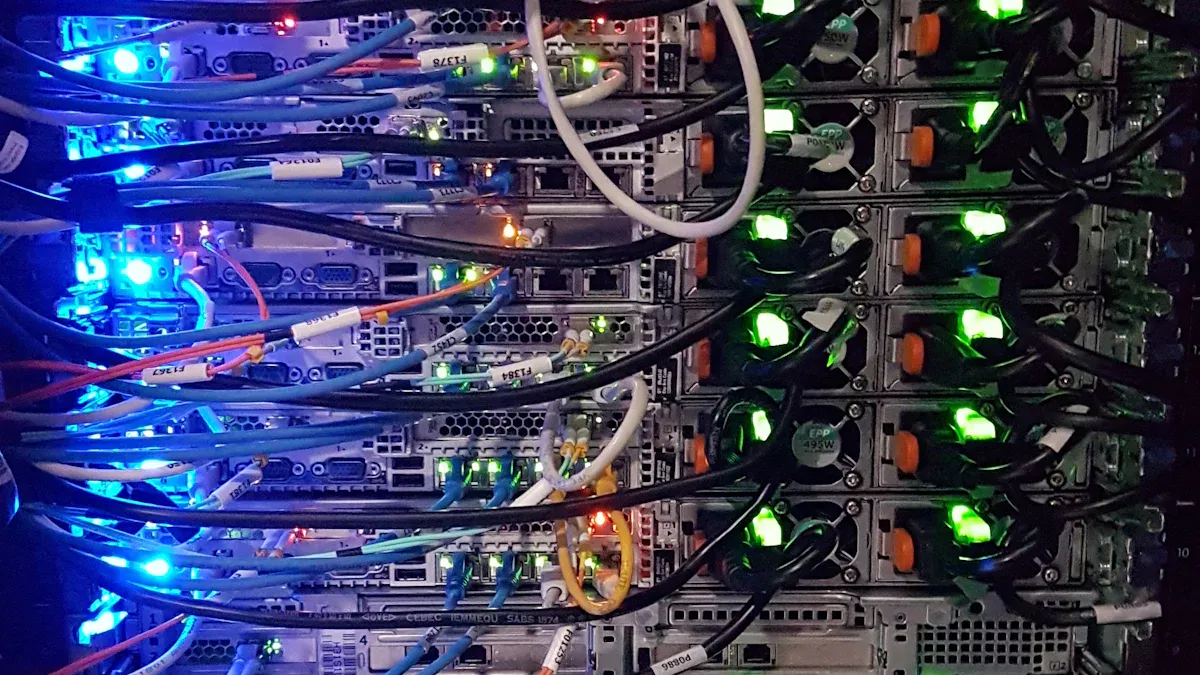

Power Distribution Units (PDUs) are essential components in modern IT and industrial environments. They distribute electrical power from a single source to multiple devices, ensuring that equipment operates efficiently and reliably. I’ve seen how PDUs act as the backbone of power management in data centers, server rooms, and industrial facilities. Without them, maintaining consistent power supply across multiple devices would be nearly impossible.

PDUs come in various types, including basic, metered, and intelligent models. Intelligent PDUs, like those offered by NBYOSUN, provide advanced features such as real-time monitoring, remote management, and environmental awareness. These capabilities allow operators to optimize power usage, reduce energy waste, and prevent overloads. For example, intelligent rack PDUs can reduce energy waste by up to 20% through improved monitoring and control.

In commercial settings, PDUs enhance reliability and efficiency. A table below highlights some of their key benefits:

| Feature/Benefit | Evidence |

|---|---|

| Reliability Increase | Implementing ATS PDUs can increase reliability by 25% in facilities with backup power. |

| Energy Waste Reduction | Intelligent rack PDUs can reduce energy waste by up to 20% through improved monitoring. |

| Enhanced Control | Switched PDUs allow remote management, increasing efficiency and minimizing downtime. |

| Real-time Monitoring | Smart PDUs enable real-time monitoring of power consumption, aiding in energy conservation. |

| Detailed Metrics | PDUs provide voltage, current, and power factor metrics for precise monitoring. |

These features make PDUs indispensable for businesses aiming to improve operational efficiency and sustainability.

How PDU Manufacturers Ensure Modern Efficiency Standards

PDU manufacturers play a critical role in meeting modern efficiency standards. They design solutions that optimize power usage, minimize waste, and comply with regulatory guidelines. I’ve noticed that companies like NBYOSUN prioritize energy-efficient designs to help businesses lower operational costs and meet sustainability goals.

Modern PDUs often include advanced energy monitoring capabilities. These features provide real-time insights into power usage, allowing operators to identify inefficiencies and take corrective actions. For instance, NBYOSUN’s intelligent PDUs feature an LCD display for precise energy monitoring, ensuring optimal power distribution. This level of control not only reduces energy consumption but also supports broader environmental objectives.

Manufacturers also focus on innovation to stay ahead of industry demands. Many PDUs now integrate seamlessly with Data Center Infrastructure Management (DCIM) software, enabling operators to monitor and manage power distribution remotely. This capability is particularly valuable in today’s digital landscape, where remote work and cloud computing have increased the need for resilient and efficient power systems.

The Importance of Reliable Power Distribution Systems in IT and Industrial Environments

Reliable power distribution is vital for IT and industrial environments. I’ve observed how even minor power interruptions can lead to significant downtime, affecting productivity and revenue. PDUs ensure consistent power supply, reducing the risk of outages and equipment failures.

Modern data centers, characterized by high power density, require precise power distribution to avoid overloads and ensure stable performance. The rise of hyperscale and edge computing facilities has further increased the demand for intelligent PDUs capable of managing decentralized power loads efficiently. Companies are also adopting energy-efficient PDUs to meet regulatory requirements and sustainability goals.

A comparison of three-phase and single-phase PDUs illustrates their impact on reliability:

| Feature | Three-Phase PDUs | Single-Phase PDUs |

|---|---|---|

| Power Management | Handles high and consistent power needs | Limited capacity |

| Monitoring Capabilities | Energy consumption monitoring available | Basic monitoring |

| Efficiency | Maximizes data center operations | Less efficient |

| Uptime Reliability | Reduces chances of downtime | Higher risk of downtime |

Built-in meters in modern PDUs enable continuous monitoring of power quality. This proactive approach helps identify and resolve issues like voltage dips and power interruptions before they affect reliability. Proper grounding and isolation further enhance safety and stability, making PDUs a cornerstone of efficient power management in IT and industrial sectors.

Key Ways PDU Manufacturers Boost Efficiency

Advanced Technology Integration

Smart Monitoring and Data Analytics

I’ve seen how advanced technology integration revolutionizes power management. PDU manufacturers now incorporate smart monitoring and data analytics into their products, enabling real-time insights into power usage. For instance, companies like Schneider Electric and APC have introduced PDUs with advanced energy monitoring features. These tools allow data centers to optimize power usage and minimize waste effectively. Vertiv and Server Technology also offer intelligent PDUs that provide real-time power usage data, helping operators identify inefficiencies and take corrective actions.

The impact of these technologies is evident in real-world applications. A large data center that implemented smart PDUs reported a 20% reduction in energy costs by monitoring energy consumption across multiple racks. Similarly, a commercial office building enhanced its energy reporting capabilities and achieved a 15% reduction in energy costs. These examples highlight how smart monitoring and analytics drive efficiency and cost savings.

Automation and Remote Management

Automation and remote management capabilities further enhance operational efficiency. Eaton’s Intelligent Power Manager (IPM) software, integrated into its PDUs, automates virtual environments and supports major virtualization platforms. This level of automation reduces manual intervention, saving time and resources. Additionally, tools like the Visual Power Manager (VPM) provide live data center maps and intelligent reporting, streamlining monitoring processes.

Remote management features allow operators to control power distribution from anywhere. I’ve noticed how this flexibility minimizes downtime and ensures uninterrupted operations. For example, NBYOSUN’s smart PDUs support remote management through LAN, WAN, or the Internet, giving businesses unparalleled control over their power systems.

Customization for Specific Needs

Tailored Solutions for Diverse Industries

PDU manufacturers excel at providing tailored solutions to meet the unique needs of various industries. Ningbo YOSUN Electric Technology Co., Ltd., for example, offers customizable PDUs with features like real-time power usage monitoring and surge protection. These tailored solutions enhance operational efficiency and safeguard critical equipment. Organizations deploying intelligent PDUs have reported energy savings of up to 20%, directly lowering operational costs.

Modular and Scalable Designs

Modular and scalable designs are another way manufacturers address diverse requirements. Modular PDUs offer flexibility, allowing businesses to adapt their power distribution systems as their needs evolve. This adaptability is particularly beneficial for industries like data centers and edge computing, where scalability is crucial. Features like energy-saving modes and real-time monitoring further enhance efficiency by reducing power consumption based on real-time demand.

A comparison of key features illustrates their impact:

| Feature | Impact on Efficiency |

|---|---|

| Energy-saving modes | Reduces power consumption by adjusting power distribution based on real-time demand. |

| Real-time monitoring | Enables precise energy management, leading to operational cost reductions. |

| Modular designs | Offers flexibility to adapt to various industrial environments. |

Energy-Saving Designs

Reducing Energy Waste

Energy-saving designs play a critical role in reducing waste. Smart PDUs provide real-time power usage data, allowing operators to identify energy-intensive equipment and implement corrective measures. Load balancing features distribute power evenly, minimizing energy waste. High-efficiency transformers integrated into smart PDUs enhance energy efficiency by 2% to 3%, further contributing to cost savings.

Improving Power Conversion Efficiency

Improving power conversion efficiency is another focus area for PDU manufacturers. By optimizing power distribution and reducing losses during conversion, modern PDUs ensure that more energy is utilized effectively. This not only lowers electricity bills but also supports sustainability goals. For example, Target’s ENERGY STAR-certified data centers saved 261,000 kWh annually by powering down unloaded PDUs, demonstrating the tangible benefits of energy-efficient designs.

The Broader Impact of Efficient PDUs

Reducing Operational Costs Through Energy Optimization

Efficient PDUs significantly lower operational costs by optimizing energy usage. I’ve seen how smart PDUs provide real-time power usage data, enabling businesses to identify inefficiencies and take corrective actions. For example, high-efficiency transformers integrated into these units improve energy efficiency by 2% to 3%, which translates into substantial cost savings over time. Additionally, features like load balancing distribute power evenly across devices, minimizing energy waste and preventing costly circuit overloads.

The financial benefits of energy optimization are particularly evident in large-scale operations. Many data centers have reported up to 20% energy savings by combining metered PDUs with server consolidation and airflow optimization. These savings not only reduce electricity bills but also enhance overall operational efficiency. The table below highlights the broader impact of efficient PDUs on cost reduction:

| Evidence Type | Statistic/Impact |

|---|---|

| Energy Savings | Up to 20% energy savings |

| Downtime Cost Reduction | Reduced downtime costs |

| Operational Efficiency | Improved efficiency through real-time monitoring and load balancing |

| Energy Waste Reduction | High-efficiency transformers improve energy efficiency by 2% to 3% |

| Load Balancing | Minimizes energy waste by distributing power evenly across devices |

By investing in advanced PDUs, businesses can achieve long-term cost reductions while ensuring reliable operations.

Supporting Sustainability Goals with Reduced Energy Waste

Efficient PDUs also play a vital role in supporting sustainability initiatives. I’ve noticed how high-density PDUs enable organizations to reduce their carbon footprint by optimizing power distribution and monitoring. These units provide real-time insights into energy consumption, allowing businesses to implement energy-saving measures that align with their environmental goals.

For instance, remote monitoring capabilities help identify inefficiencies, while load balancing ensures that power is distributed evenly across devices. High-efficiency transformers further enhance energy efficiency, contributing to measurable improvements in sustainability. The table below outlines some of the key impacts:

| Improvement Type | Measurable Impact |

|---|---|

| Energy efficiency increase | 2% to 3% |

| Reduction in energy waste | Significant cost savings |

| Load balancing capabilities | Minimizes energy waste |

These features not only reduce energy waste but also help businesses meet regulatory requirements and demonstrate their commitment to environmental responsibility.

Enabling Scalability for Growing Businesses and Networks

As businesses expand, their power needs grow. I’ve seen how scalable PDUs provide the flexibility required to accommodate these changes seamlessly. Modular designs allow for easy upgrades and expansion without disrupting operations. This adaptability ensures that new equipment can be integrated into existing systems without the risk of overloading circuits or compromising reliability.

For example, rack PDUs with flexible configurations enable businesses to scale their IT infrastructure efficiently. Compact designs optimize space in racks or cabinets, making it easier to add new devices as needed. The table below highlights the scalability benefits of modern PDUs:

| Feature | Benefit |

|---|---|

| Modular designs | Allow for seamless upgrades and expansion without disrupting operations. |

| Capacity to prevent overloading | Ensures that new equipment can be added without risk of failure. |

| Flexible configurations | Enable growth without needing to replace the entire unit. |

| Compact designs | Optimize space in racks or cabinets, accommodating additional devices. |

By investing in scalable PDUs, businesses can minimize downtime, reduce operational disruptions, and align their infrastructure with future growth.

Challenges PDU Manufacturers Face in Driving Efficiency

Balancing Cost and Innovation in Product Development

Balancing cost and innovation remains one of the most significant challenges for PDU manufacturers. I’ve observed how the demand for advanced features like real-time monitoring and automation often requires substantial investment in research and development. However, these costs can create barriers, especially for smaller enterprises.

Some of the key challenges include:

- High initial investment and maintenance costs, which hinder small and medium enterprises (SMEs) from adopting new technologies.

- The complexity of power management systems, which increases the need for specialized personnel and raises operational expenses.

- Cybersecurity risks associated with connected PDUs, requiring additional investments in robust security measures.

- Supply chain disruptions, such as the global semiconductor shortage, which affect the availability of essential components.

These factors make it difficult for manufacturers to innovate while keeping their products affordable. I’ve seen how companies like NBYOSUN address this by focusing on scalable and modular designs, which allow businesses to adopt advanced features incrementally.

Adapting to Rapid Technological Changes in Power Management

The rapid pace of technological advancements in power management presents another challenge. Manufacturers must continuously innovate to stay competitive, but this often comes with its own set of difficulties. For instance, integrating new PDUs with existing systems can be complex and time-consuming. This complexity leads to delays and additional costs, which can strain resources.

Cybersecurity also becomes a critical concern as more PDUs incorporate smart features. I’ve noticed how connected devices increase the risk of cyberattacks, requiring manufacturers to invest heavily in security protocols. Additionally, the high initial costs of adopting advanced PDUs can deter smaller businesses from upgrading their systems.

Despite these challenges, I believe manufacturers like NBYOSUN are making strides by integrating their products with Data Center Infrastructure Management (DCIM) software. This approach simplifies system integration and enhances overall efficiency.

Meeting Regulatory and Environmental Standards

Compliance with regulatory and environmental standards is essential for PDU manufacturers. These standards ensure product safety, environmental sustainability, and compatibility across regions. However, meeting these requirements can be resource-intensive.

Here’s a breakdown of key certifications and their significance:

| Certification | Description |

|---|---|

| UL | Ensures safety and performance standards, minimizing risks like electrical shocks and fire hazards. |

| CE | Indicates compliance with EU regulations for health, safety, and environmental protection. |

| RoHS | Ensures products are free from hazardous materials like lead and mercury, promoting environmental safety. |

| IEC | Ensures compatibility across different countries and regions, defining plug types and voltage ranges. |

| ISO | Focuses on quality management and continuous improvement in manufacturing processes. |

| NEMA | Classifies enclosures based on protection against external conditions like dust and water. |

I’ve seen how these certifications not only enhance product reliability but also build trust with customers. However, achieving and maintaining compliance requires significant investment in testing, documentation, and process improvements. Manufacturers must also adapt to evolving regulations, which adds another layer of complexity.

By addressing these challenges head-on, PDU manufacturers can continue to drive efficiency while meeting the demands of a rapidly changing market.

How to Choose the Right PDU Manufacturer

Key Factors to Consider When Selecting a Manufacturer

Reputation and Experience in the Industry

When selecting a PDU manufacturer, reputation and experience are critical indicators of reliability. I always evaluate a manufacturer’s track record to ensure they can deliver high-quality products and services. Established companies like YOSUN, with over 25 years of expertise, demonstrate their ability to meet diverse client needs. Their partnerships with industry leaders such as Lenovo and Schneider further validate their credibility.

Several measurable factors can help assess a manufacturer’s reputation and experience:

| Factor | Description |

|---|---|

| Customer Support Features | The level of assistance and training provided by the manufacturer. |

| Response Time | The speed at which the manufacturer addresses customer inquiries. |

| Certifications | Industry standards that the manufacturer meets, ensuring product quality. |

| Market Reputation | The overall perception of the manufacturer in the industry. |

| Customer Feedback | Reviews and ratings from users regarding product performance. |

| Sustainability | Commitment to environmentally friendly practices. |

These factors provide a comprehensive view of a manufacturer’s reliability and their ability to meet modern efficiency standards.

Range of Products and Customization Options

A diverse product range and customization options are equally important. Manufacturers like YOSUN offer a wide variety of PDUs, including Basic, Metered, Smart, and Heavy-Duty models. This versatility ensures compatibility with different industries, from data centers to cryptocurrency mining operations.

Key criteria to evaluate the range of products and customization options include:

| Criteria | Description |

|---|---|

| Modular Designs | Allows for scalability and adaptability in data center configurations. |

| Real-time Monitoring | Enables immediate insights into power usage and system performance. |

| Remote Management Capabilities | Facilitates control and adjustments from off-site locations. |

| Protective Features | Includes surge and overload protection to ensure system reliability. |

| Customization Options | Tailored solutions for specific industry needs, such as rack configurations. |

These features ensure that the manufacturer can provide solutions tailored to your operational requirements.

Questions to Ask Before Making a Decision

Asking the right questions can simplify the decision-making process. I recommend focusing on the following:

- Does the manufacturer offer scalable and modular designs to support future growth?

- What certifications do their products hold to ensure compliance with safety and environmental standards?

- How responsive is their customer support team in addressing technical issues?

- Are their PDUs compatible with existing infrastructure and management software?

- What is the total cost of ownership, including maintenance and support services?

These questions help identify manufacturers who align with your operational goals and efficiency needs.

The Role of Customer Support and Maintenance in Long-Term Efficiency

Customer support plays a pivotal role in maintaining long-term efficiency. I’ve seen how excellent support minimizes downtime and ensures smooth operations. Manufacturers offering 24/7 technical assistance and personalized training empower businesses to maximize the value of their PDUs.

Key benefits of strong customer support include:

- Quick resolution of technical issues, reducing operational disruptions.

- Proactive maintenance services that extend the lifespan of PDUs.

- Cost savings through reduced downtime and optimized performance.

Reliable customer support ensures that your investment in PDUs delivers consistent returns over time. Manufacturers like YOSUN, known for their robust support services, exemplify this commitment to customer success.

The Future of PDU Manufacturing and Efficiency

Emerging Trends in PDU Technology

I’ve observed how the PDU industry is evolving rapidly, driven by the need for efficiency and sustainability. Modular PDUs have emerged as a game-changer, offering customization options that adapt to dynamic environments like data centers. These designs allow businesses to scale their power distribution systems without overhauling existing setups. Energy-efficient designs are another significant trend. They focus on reducing power consumption and carbon footprints, aligning with global sustainability goals.

The integration of artificial intelligence (AI) is also transforming the landscape. AI-powered PDUs enhance predictive maintenance and energy management, ensuring optimal performance. Sustainability has become a priority, with innovations aimed at reducing energy waste and promoting eco-friendly practices. Features like real-time monitoring and dynamic adjustments based on data trends are now standard in advanced PDUs.

| Trend | Description |

|---|---|

| Modular PDUs | Allow customization based on current and future needs, ideal for dynamic environments like data centers. |

| Energy-Efficient Designs | Focus on reducing power consumption and carbon footprint, aligning with sustainability efforts. |

| AI Integration | Enhances predictive capabilities for maintenance and energy management in PDUs. |

| Sustainability Focus | Innovations aimed at reducing energy consumption and promoting eco-friendly practices. |

These trends highlight how PDU manufacturers are shaping the future of power distribution with cutting-edge technology.

The Role of AI and IoT in Power Distribution

AI and IoT are revolutionizing power distribution. I’ve seen how AI algorithms improve efficiency through real-time monitoring and predictive maintenance. For example, smart grids now utilize IoT devices and AI analytics to control energy distribution dynamically. This ensures that power flows efficiently, even in complex systems.

Predictive analytics is another breakthrough. It can foresee disruptions, enhancing grid reliability and resilience. By processing data from numerous sensors, AI optimizes energy flow, which is especially crucial for integrating renewable energy sources. These advancements not only improve operational efficiency but also support sustainability initiatives.

- AI algorithms enhance power distribution efficiency through real-time monitoring and predictive maintenance.

- Smart grids utilize IoT devices and AI analytics for real-time energy distribution control.

- Predictive analytics can foresee disruptions, improving grid reliability and resilience.

- AI optimizes energy flow by processing data from numerous sensors, crucial for integrating renewable energy sources.

The combination of AI and IoT is setting new benchmarks for efficiency and reliability in power management.

How Manufacturers Like NBYOSUN Are Preparing for a Sustainable Future

Sustainability has become a cornerstone of the PDU industry. Leading manufacturers like NBYOSUN are adopting green technologies to reduce environmental impact and improve energy efficiency. I’ve noticed how they incorporate recyclable materials into their PDUs, supporting a circular economy. Their energy-efficient designs, featuring real-time power monitoring and intelligent load balancing, minimize energy consumption.

| Manufacturer | Key Energy-Efficient Features |

|---|---|

| Schneider Electric | EcoStruxure IT platform for advanced energy analytics |

| Eaton | Real-time monitoring and modular designs |

| YOSUN | LCD display and surge protection for efficiency |

Many manufacturers are also transitioning to renewable energy sources for their production facilities. This shift helps achieve net-zero carbon emissions. NBYOSUN exemplifies this commitment by integrating advanced features like remote management and environmental monitoring into their PDUs. These innovations align with global sustainability goals while ensuring operational efficiency.

By focusing on eco-friendly practices and energy-efficient technologies, manufacturers like NBYOSUN are not just meeting current demands but also paving the way for a sustainable future.

Case Study: NBYOSUN’s YS31542-36C13-6C19-M Smart PDU

Overview of the YS31542-36C13-6C19-M Smart PDU

The YS31542-36C13-6C19-M Smart PDU represents a significant leap in power distribution technology. Designed by NBYOSUN, this advanced unit addresses the growing demand for energy-efficient and reliable power management in data centers and industrial environments. It combines cutting-edge features like real-time monitoring, remote management, and environmental awareness to optimize energy usage and enhance operational efficiency.

This PDU integrates seamlessly with Data Center Infrastructure Management (DCIM) software, providing operators with detailed insights into power consumption and environmental conditions. Its customizable design ensures compatibility with diverse setups, making it a versatile solution for businesses of all sizes. By prioritizing efficiency and sustainability, NBYOSUN has created a product that not only meets but exceeds modern power management standards.

Key Features and Benefits

Real-Time Monitoring and Environmental Awareness

The YS31542-36C13-6C19-M Smart PDU excels in real-time monitoring, offering precise metrics such as current, voltage, wattage, and power factors. These metrics allow operators to track energy consumption and identify inefficiencies. For example, the unit’s ability to log peak loads helps prevent overloads, ensuring uninterrupted operations.

Environmental awareness is another standout feature. The PDU monitors temperature and humidity levels, enabling proactive adjustments to maintain optimal conditions for sensitive equipment. This capability reduces the risk of overheating and extends the lifespan of critical infrastructure.

Tip: Facilities using intelligent PDUs like this one have reported energy savings of up to 20%, demonstrating the tangible benefits of real-time monitoring.

Remote Management Capabilities

Remote management is a game-changer for modern power distribution. The YS31542-36C13-6C19-M supports remote access through LAN, WAN, or the Internet, allowing operators to control power distribution from anywhere. This flexibility minimizes downtime and ensures quick responses to potential issues.

For instance, businesses can use remote management to power down unused equipment, significantly reducing energy waste. Target’s ENERGY STAR-certified data centers achieved annual savings of 261,000 kWh by implementing similar strategies. This feature not only enhances efficiency but also aligns with sustainability goals.

How NBYOSUN’s PDU Enhances Efficiency and Sustainability

NBYOSUN’s smart PDU optimizes energy efficiency through advanced features like energy-saving modes and intelligent load balancing. These capabilities automatically adjust power distribution based on real-time demand, reducing waste and lowering operational costs. For example, eBay utilized intelligent PDUs to cut operating costs by 50%, showcasing the potential of such technology.

The unit’s detailed energy metrics, including PUE (Power Usage Effectiveness), help facilities identify inefficiencies and implement corrective measures. A lower PUE indicates higher energy efficiency, which directly supports sustainability initiatives. The table below highlights how these features contribute to efficiency and sustainability:

| Metric | Description | Implication |

|---|---|---|

| PUE | Total facility power / IT equipment energy | Identifies inefficiencies and optimizes usage. |

| Energy-saving modes | Adjusts power distribution based on demand | Saves significant energy, reducing costs. |

| Intelligent PDUs | Provides detailed energy consumption data | Enables proactive power management. |

By integrating these features, NBYOSUN’s PDU not only enhances operational efficiency but also helps businesses achieve their environmental objectives. This makes it a valuable asset for organizations aiming to balance performance with sustainability.

Real-World Applications and Success Stories

Power Distribution Units (PDUs) have become indispensable in various industries, offering tailored solutions to meet unique operational challenges. I’ve seen firsthand how businesses leverage these devices to optimize power distribution, enhance reliability, and achieve sustainability goals. Their applications span data centers, manufacturing facilities, and even cryptocurrency mining operations, showcasing their versatility and impact.

In modern data centers, high-density PDUs play a critical role. They integrate seamlessly with Data Center Infrastructure Management (DCIM) systems, providing real-time data on voltage, current, and power consumption. This level of insight ensures reliable power distribution, even in high-density environments. For instance, a global technology company implemented intelligent PDUs to monitor energy usage across its server racks. The result? A 20% reduction in energy costs and improved uptime reliability. These outcomes highlight the transformative potential of PDUs in data-intensive industries.

Manufacturing facilities also benefit significantly from PDU technology. I’ve observed how customizable alert settings enhance operational efficiency. Businesses can configure alerts for temperature spikes, preventing overheating and system failures. Humidity monitoring ensures safe environmental conditions, maintaining product quality. For example, a pharmaceutical company utilized smart PDUs to monitor environmental conditions in its production lines. This proactive approach reduced product defects by 15%, demonstrating the tangible benefits of intelligent power management.

PDUs have also found applications in emerging sectors like cryptocurrency mining. These operations demand high power density and reliability. Smart PDUs with modular designs and real-time monitoring capabilities meet these requirements effectively. A cryptocurrency mining firm adopted NBYOSUN’s smart PDUs to manage its growing infrastructure. The company reported a 30% improvement in energy efficiency, enabling it to scale operations without compromising performance.

Note: Customizable alert settings in PDUs allow businesses to tailor notifications, reducing downtime and enhancing reliability. This flexibility ensures that power systems adapt to specific operational needs.

The success stories don’t end there. Organizations across industries have leveraged PDUs to achieve measurable improvements in efficiency and sustainability. Whether it’s reducing energy waste in data centers or maintaining optimal conditions in manufacturing facilities, PDUs have proven their value time and again. These real-world applications underscore the importance of investing in advanced power distribution solutions to stay competitive in today’s fast-paced environment.

PDU manufacturers play a critical role in enhancing operational efficiency. I’ve seen how their innovative designs, like NBYOSUN’s YS31542-36C13-6C19-M smart PDU, optimize power distribution and reduce energy waste. These advancements lead to measurable cost savings, improved sustainability, and scalable solutions for growing businesses. Selecting the right manufacturer is essential. Businesses should evaluate their options carefully to ensure the chosen solutions align with their efficiency and environmental goals. By investing in the right PDU technology, organizations can future-proof their operations and achieve long-term success.

FAQ

What is a PDU, and why is it important?

A Power Distribution Unit (PDU) distributes electrical power to multiple devices. It ensures reliable power delivery, optimizes energy usage, and prevents overloads. PDUs are essential for maintaining operational efficiency in data centers, server rooms, and industrial environments.

How does YOSUN ensure product quality?

YOSUN guarantees quality through 25 years of expertise and partnerships with industry leaders like Lenovo and Schneider. Their PDUs meet global standards, including IEC and RoHS certifications, ensuring safety, reliability, and environmental compliance.

What types of PDUs does YOSUN offer?

YOSUN provides a wide range of PDUs, including:

- Basic PDUs: For standard power distribution.

- Metered PDUs: With energy monitoring.

- Smart PDUs: Featuring remote management.

- Heavy-Duty PDUs: For high-power applications.

These options cater to diverse industries and needs.

Can YOSUN’s PDUs be customized?

Yes, YOSUN specializes in custom solutions. They design PDUs tailored to specific requirements, including modular designs, unique plug types (e.g., IEC C13/C19), and advanced features like real-time monitoring and surge protection.

How do smart PDUs improve efficiency?

Smart PDUs provide real-time energy data, enabling operators to identify inefficiencies and optimize power usage. Features like remote management and load balancing reduce energy waste, lower costs, and enhance sustainability.

What industries benefit from YOSUN’s PDUs?

YOSUN’s PDUs serve various industries, including:

- Data Centers: For reliable power distribution.

- Edge Computing: To manage decentralized loads.

- Cryptocurrency Mining: For high-density power needs.

- Manufacturing: To monitor environmental conditions.

Their versatility ensures broad applicability.

How does YOSUN support sustainability goals?

YOSUN integrates energy-efficient designs into their PDUs, reducing energy waste and carbon footprints. Features like intelligent load balancing and real-time monitoring align with global sustainability initiatives, helping businesses achieve environmental objectives.

Why choose YOSUN as a PDU manufacturer?

YOSUN combines 25 years of expertise with innovative designs and global certifications. Their customizable PDUs, strong customer support, and commitment to sustainability make them a trusted partner for efficient power solutions.

Tip: Always evaluate a manufacturer’s reputation, product range, and customization options before making a decision.

Post time: Mar-10-2025